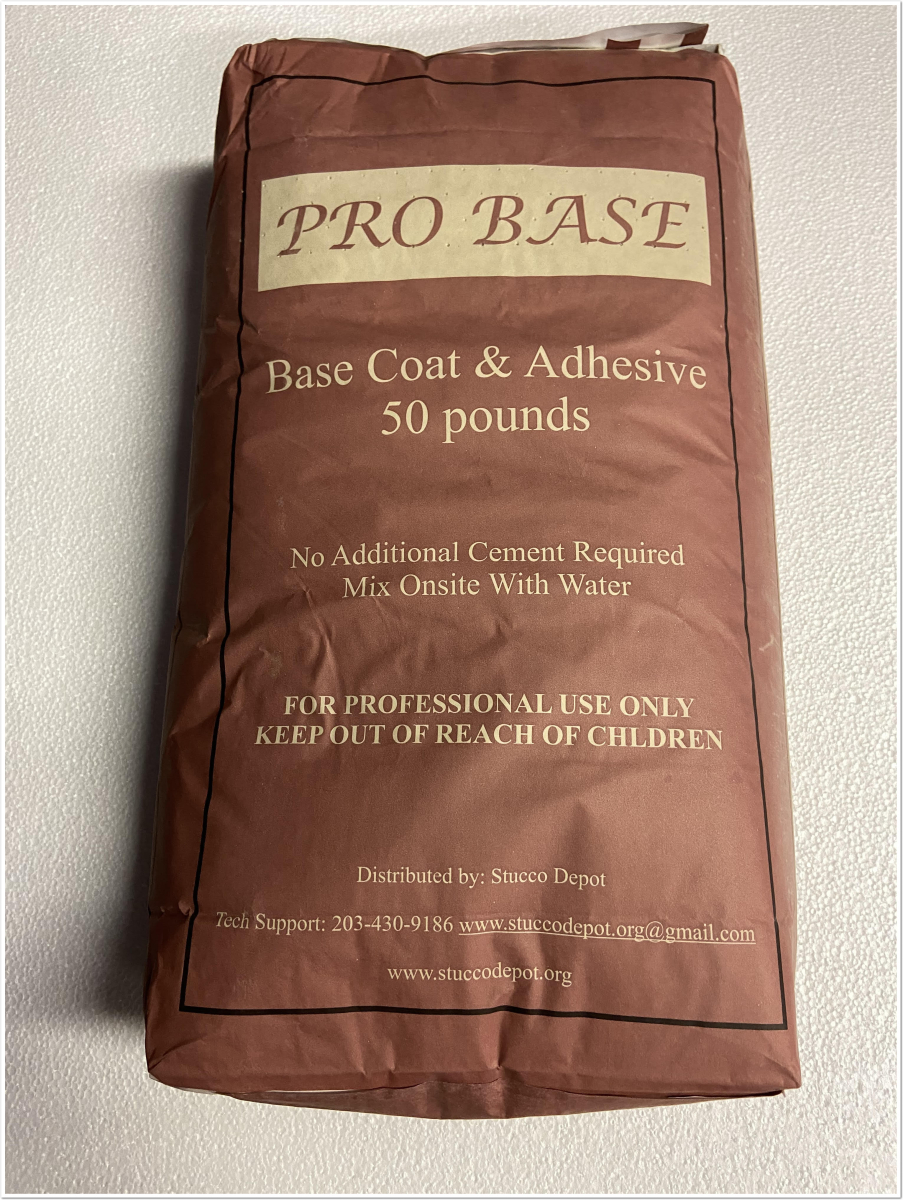

PRO BASE * Base Coat and Adhesive

Pro Base is one of our best selling products. It's a great Base Coat at a Great Price.

Once you try it you will love it!

FREE SAMPLE AVAILABLE TO NEW CUSTOMERS

Product Overview

Pro Base is a dry powder latex-modified Portland Cement Based Product designed

for use as a base coating and adhesive for expanded polystyrene foam (ESP) and

requires only water for mixing.

Features / Benefits

Dry bagged product

Water based

Base Coat and Adhesive

Consistent batching

Factory blended

Easily stored in cold climates

Mix only quantity needed

Color consistency

Convenient - just add water

Properties

Neutral color

Fine aggregates

Portland cement

Proprietary polymer blend

Coverage

To adhere EPS board to substrate approximately 50-70 sf

As a base coat to imbed fiberglass mesh 90-110 sf

As a leveling coat varies upon application and technique

Recommended Substrates

PRO BASE is designed to coat and adhesive EPS boards as well as moldings and

cornice. Can be used over stucco - concrete - concrete block - unglazed brick -

fiber mat-faced gypsum sheathing - exterior grade gypsum sheathing - cement

board - masonry (clean and unpainted) - poured in place concrete free from

release agents.

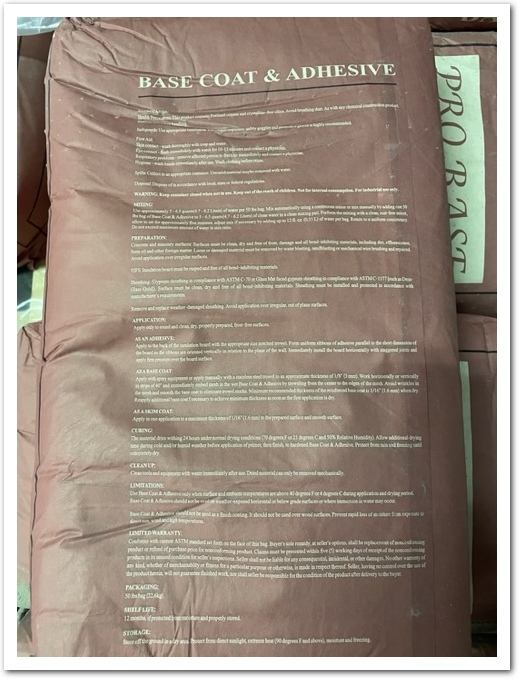

Preparation

Surface must be clean, dry, structurally sound, and free from dirt, grease or

coatings that may inhibit adhesion. Temperature must be 40 degrees or higher for

a period of 24 hours after application.

Hazard StatementHarmful if swallowed. Causes moderate eye irritation. Prolonged skin contact may cause irritation. Wash thoroughly after handling. In case of eye contact flush immediately with cool water. If skin or eye irritation persists seek medical assistance. WarrantyThe manufacturer warrants this properly handled and installed product to be free from manufacturing defects from date of purchase for a period of five years. If it is shown that the product is defective when installed by a competent installer / applicator, the manufacturer’s liability under this warranty is to supply replacement product. There are no other warranties expressed or implied and the manufacturer or manufacturer’s representative shall determine the remedies. We make no other warranties and expressly disclaim any warranties of merchantability or fitness for a particular purpose. See full warranty schedule in our product literature submittal package. Limitations Protect from freezing. Do not apply in temperatures above 110-F or below 38 F. The ambient and surface temperature must remain within these temperature ranges until fully cured (minimum 24 hours). Protect all work from inclement weather until fully cured. Do not add any other materials to this product without written permission from the manufacturer. This is not a finished product and must have a finish layer applied. |

Instructions

Application

Clean-upUse fresh water to clean tools or droppings before product dries.

|